Laser perforating

We offer state-of-the-art laser perforating services that consistently outperform traditional mechanical methods.

Our LaserSharp® technology features a high-speed, non-contact process.

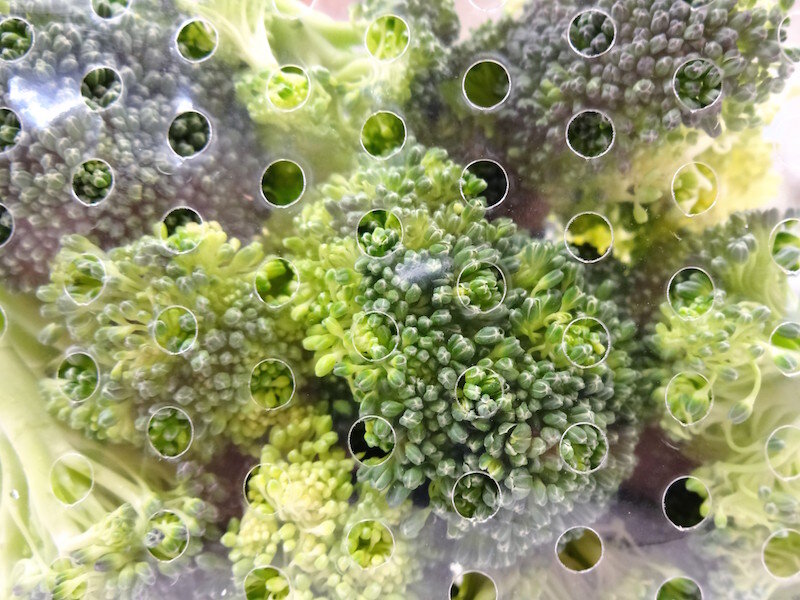

Our non-contact process is capable of either penetrating entirely through a material or only partially penetrating select layers. Unlike mechanical perforating which often compromises the strength and integrity of the film, creating unwanted tears, our laser perforating process produces cauterized holes that are uniform, strong, and free of residue or drops.

The resulting perforations improve the packaging atmosphere by controlling the ideal amount of oxygen, carbon dioxide, and moisture which helps to extend shelf life and maintain product flavor and appearance.

Laser perforating

Innovate with us.

Advantages

Features adjustable hole size, location, frequency, and patterns

Offers round shapes free of residue or drops

Delivers thermally sealed edges that reduce propagation and tear

Allows precise registration to print on product packaging

Features high-speed, non-contact process

Extends shelf life of perishable foods

Regulates oxygen, vapor, and gas transmission rates

Reduces condensation and bacteria growth

Integrates venting for rapid fill packaging

Applications

Perishable Food Packaging

Modified Atmosphere Packaging

Breathable Films

Microwavable Steam Release

X-Fresh Breathable Packaging