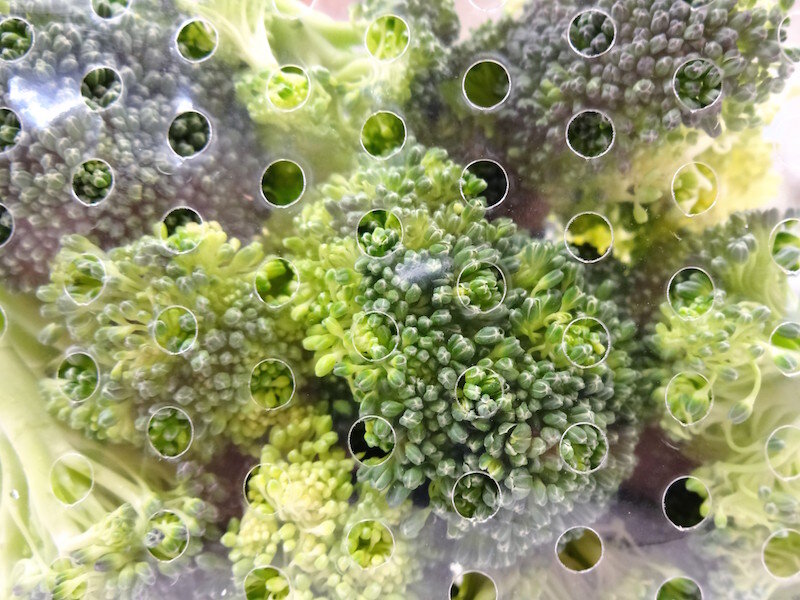

Breathable Packaging

Unlike mechanical methods, laser processing is an affordable and effective way to control the amount of oxygen and moisture inside a package. FlexPak’s breathable packaging solutions leverage patented technology to preserve a variety of perishable food products from fruits and vegetables to meat and seafood.

Laser for high-performance packaging

FAQs

What are the advantages to Breathable Packaging?

When you choose FlexPak, you gain the power of laser-enabled packaging that doesn’t disappoint — extending shelf life and keeping food products fresh and flavorful.

-

✓Reduce bacteria growth and build up of gases inside the package

✓Facilitate gaseous needs for aerobic respiration

✓Maintain oxygen transmission rates with laser micro perforated films

✓Maintain hermetic capabilities with laser scored films

How can Breathable Packaging be implemented?

We understand converters and brand owners have different productions needs and requirements, so we are happy to offer a variety of breathable packaging applications.

-

Microwavable packaging

Modified-atmosphere produce packaging

Infusion packages for consumables such as tea, cannabis, salts, etc.

Carbon dioxide release for meat and seafood packaging

Venting

Air evacuation